products

Fasteners to reach perfection and excellence.

To produce your fasteners in the most efficient way as possible HSP Fasteners uses several production technologies. The production technologies we are experienced with are listed below. Combinations between production technologies are possible and sometimes even beneficial (e.g. first cold forging and then than turning).

Hot- and cold forging

Hot- and cold forging – our specialty – is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer or die. Forging is often classified according to the temperature (cold- and hot forging). HSP Fasteners is specialized in cold forging solutions (Kaltfließpressteile)!

Advantages of forging can be that a piece is stronger and that this technology is more cost efficient in large series than for example the same part that is produced according machining technologies.

Below you can see an illustration of the forging process of a screw.

Machining technologies

Machining technologies – is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. Examples of machining technologies are turning, milling, boring etc. Advantages of this technique lie manly in high the precision of the produced parts and the creation of complex shapes.

Below you can see an illustration of the milling and turning process.

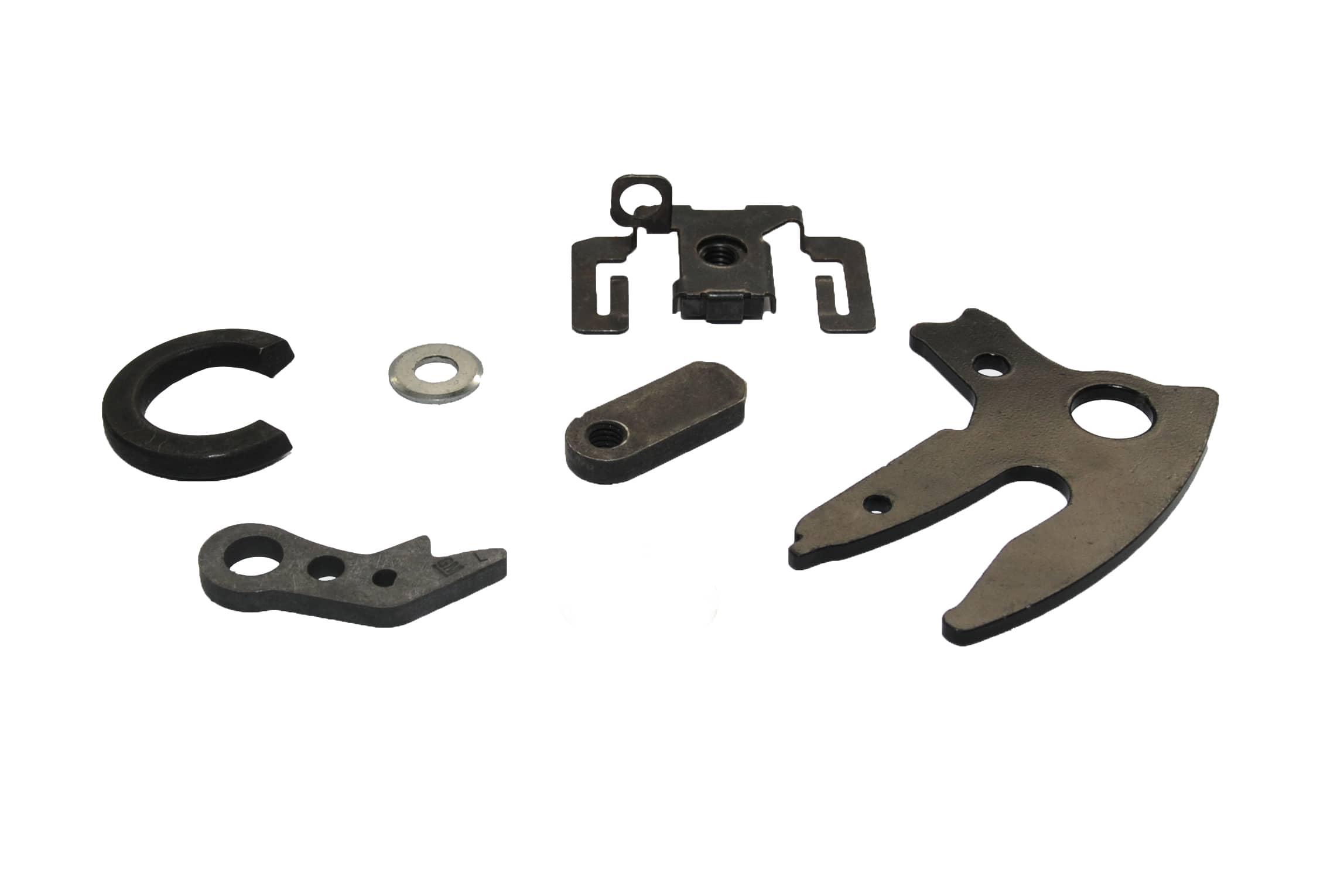

Stamping technologies

Stamping technologies – (also known as pressing or Stanzteile) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

Below you can see an illustration of the stamping process.